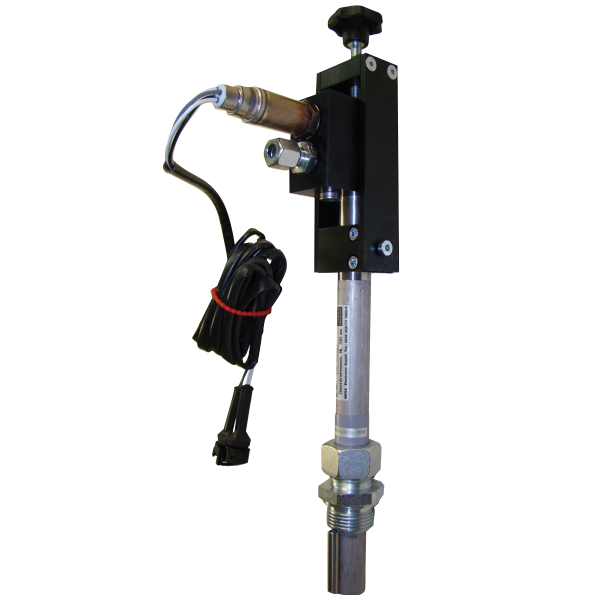

OXYGEN PROBE ME

- Designed for difficult working condition

- Based on the brand new ZrO2 C3M electrolyte

- Ideal for use in carburizing, neutral hardening and gas generator applications.

- Every probe is 100% tested with certification, certificates are enclosed with each probe.

- High reliability of the probe thanks to a simple and effective concept

- Interchangeable with all oxygen probes or carbon sensors.

- Reduces stress on the 4-bore tube, reducing incidents of breakages.

- Low investment resulting in an important improvement of heat treatment

ME-S/W probe was developed for very difficult working conditions. It is based on the new ZrO2 C3M electrolyte and offers excellent accuracy for the measurement of carbon potential (%C) and temperature (°C) The oxygen probe is suitable for direct connection to all reputable C-level control systems. ME-S/W probe allows a very precise value of oxygen concentration in an industrial furnace to be obtained.

The zirconia carbon sensor has been used for nearly three decades to control the carbon potential in many carburizing applications. The reproducible internal resistance of the probe permits simple calculation of its residual service life. The probe can be used in any atmospheric heat treatment process e.g. carburizing.

Output

0 to 1200 mVReadout impedance

% Carbon sensors should be used with controlling, recording andindicating instruments having input impedance of 10 megohms or higher.

Accuracy

±0.05 weight percent carbon in normal operating rangeWorking temperature:

600°C to 1150°CProbe types:

ME-S – with thermocouple or ME-W without thermocoupleMechanical shock:

Resist mild mechanical shock. Handle carefullyThermal shock:

Please place into hot furnace or remove from hot furnace during 10 minute time intervalAvailable length (mm):

500mm, 650mm, 750mm, 850mm, 1000mm, 1200mm, 1350mmReference air:

Uncontaminated dry air at maximum rate of 1-6 l/hCleaning air:

Uncontaminated dry air at maximum rate of 300 l/h (see user manual for more cleaning recommendation)

OUR PRODUCT IN THE INDUSTRY

This unit is designed for use in the heat treatment industry